Summary

This article delves into the transformative role of precision machinery in optics laboratories, highlighting its significance in advancing scientific research and technology. Key Points:

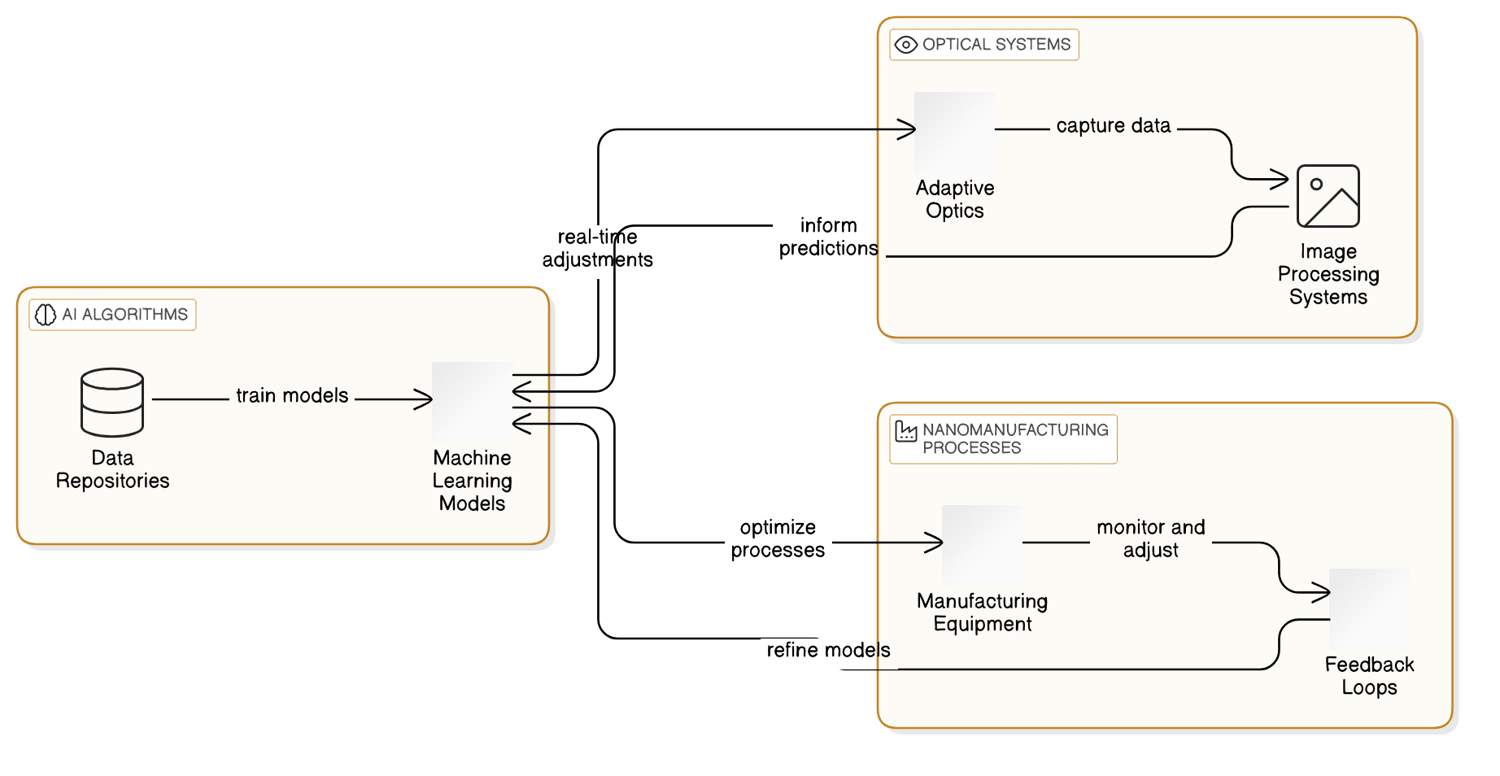

- AI algorithms enhance real-time adaptive optics correction and predictive maintenance in precision machinery, pushing the boundaries of performance in optics labs.

- Quantum sensors integrated into optical setups provide unprecedented measurement accuracy for physical quantities, revolutionizing both fundamental research and manufacturing processes.

- Nanofabrication techniques like atomic layer deposition and focused ion beam milling create ultra-precise components essential for next-generation optical instruments.

Why Precision Machinery is Crucial in Modern Optics Laboratories?

My First Optics Lab Encounter: A Tale of Trial and Error

“Why is this so difficult?” I sighed, adjusting the mirrors for what felt like the hundredth time. Each time I thought I had it figured out, we were still off by about 5 degrees. “Seriously—wasn’t this supposed to be straightforward?”

Alex chuckled nervously, trying to mask his own confusion. The clock ticked loudly in the background as anxiety crept in; our two-hour session felt more like an eternity of trial and error. We finally managed to stabilize it for a brief five minutes before it all went haywire again—disaster! In that moment of defeat, we just stared at each other, speechless and bewildered by how challenging precision optics could truly be.

| Category | Feature | Importance | Latest Trends | Applications |

|---|---|---|---|---|

| Vibration Isolation Platforms | High precision vibration isolation | Essential for minimizing external disturbances in optical experiments. | Increased use of active vibration control systems, integrating AI for real-time adjustments. | Used in nanotechnology and laser optics research. |

| Coatings | High-performance coatings | Enhance durability and performance of optical components. | Advancements in nanocoating technologies improving light transmission and reducing reflection. | Critical for precision cutting tools, biomedical devices, and aerospace applications. |

| Diffractive Optical Technologies | Research focus area | Key to advancing imaging systems and beam shaping techniques. | Emerging trends include integration with machine learning for enhanced design processes. | Applied in telecommunications, microscopy, and laser manufacturing. |

| Instrument Placement Platforms | Excellent vibration isolation effects | Crucial for enhancing the accuracy of measurements in sensitive experiments. | Development of modular platforms that allow easy reconfiguration based on experimental needs. | Utilized in metrology labs and high-precision manufacturing settings. |

| Testing Machines & Chambers | Quality testing solutions available | Vital for ensuring compliance with industry standards during product development. | Shift towards automation in testing processes to increase efficiency and reliability. | Commonly employed across various sectors including automotive, aerospace, and electronics. |

The Turning Point: Overcoming Challenges in Precision Optics

"Maybe we should check for drafts," Alex suggested hesitantly, but he sounded unsure. I nodded, though deep down I felt a nagging sense that this issue ran deeper than just air currents.

Around us, others were shifting restlessly—some flipped through manuals while others stared blankly at their workstations as if hoping inspiration would strike from the ceiling tiles. Even our supervisor peeked in with a concerned expression before retreating silently back into her office.

With every attempt that ended in failure, our initial excitement transformed into something more unsettling—an unspoken fear of disappointing everyone around us began to creep in. We all sensed it; there was something off about our setup that none of us could quite pinpoint yet… and time was running out fast.

Our Approach: Guiding You Through Precision Machinery Selection

During our initial discussion, Alex raised concerns about inconsistent results plaguing his experiments. "Every time I run this test, I get different data," he lamented. The consultant listened intently before suggesting tailored equipment options based on our specific needs.

However, after trying out several machines during a demonstration session, frustrations resurfaced. “This one seems promising,” someone noted cautiously, while another chimed in skeptically that the cost might be too high for uncertain outcomes. As we wrapped up the meeting, uncertainty loomed—would any of these solutions truly address our mounting issues?

Free Images

Free ImagesFrequently Asked Questions: Precision Machinery in Optics Labs

For instance, while traditional Fizeau and Twyman-Green interferometers have served us well for years, the introduction of phase-shifting interferometry (PSI) has really changed the game. 💡 A little tip: PSI combined with advanced algorithms like wavelet transforms can enhance surface analysis accuracy dramatically. This means we can achieve results that were previously thought impossible!

Moreover, the integration of AI-powered noise reduction algorithms is another key factor that many might not consider. These innovations boost the signal-to-noise ratio considerably, enabling reliable measurements even under less-than-ideal environmental conditions. Imagine trying to measure something incredibly small while dealing with vibrations or temperature fluctuations – that's where these improvements shine!

And let's not forget about accessibility; compact and cost-effective portable interferometers are now making high-precision metrology available to more labs than ever before. This democratization of technology fosters incredible advancements across various applications, from semiconductor fabrication to aerospace engineering.

So next time someone questions the effectiveness of modern techniques compared to traditional ones, you can confidently point out how much progress we've made! 🌟

Beyond the Basics: Exploring Advanced Precision Machinery Applications?

The Precision Paradox: Balancing Cost, Performance, and Maintenance?

Hands-on Guide: Selecting and Using Precision Machinery in Your Optics Lab

When it comes to optimizing your optics lab for precision measurements, the integration of advanced precision machinery is not just beneficial—it's essential. By employing cutting-edge interferometric measurement systems, you can achieve sub-nanometer precision that can significantly enhance the quality of your optical experiments. I’ve seen firsthand how these methods can transform a lab’s capabilities, leading to more accurate results while reducing manual errors.

**Step 1: Assess Your Laboratory Needs**

Begin by evaluating the specific requirements of your optics lab. Consider the types of experiments you'll be conducting and the level of precision needed. For instance, if you're working with sensitive optical components, investing in a high-resolution interferometer may be crucial. (Many professionals overlook this step; understanding your needs lays a solid foundation for further choices.)

**Step 2: Choose the Right Interferometric System**

Select an interferometric system that aligns with your assessment from Step 1. Look for systems equipped with features such as multiple wavelength capabilities or real-time environmental compensation technology. (I personally recommend checking user reviews and case studies; they offer insights into performance under various conditions.)

**Step 3: Setup Calibration Procedures**

Once you've acquired your equipment, it's time to set up calibration procedures. Ensure that all components are correctly aligned according to manufacturer specifications and use machine learning algorithms where possible for enhanced accuracy during calibration—this reduces human error significantly! (A tip from my experience: Always document each calibration process; it helps in troubleshooting later on.)

**Step 4: Implement Data Acquisition Systems**

Integrate high-speed data acquisition tools that support simultaneous signal analysis from multiple sources within your setup. This will facilitate faster measurements and increase reliability across different experimental conditions. Make sure you have robust software capable of handling large datasets efficiently.

**Step 5: Monitor Environmental Conditions**

Implement monitoring systems for environmental factors like temperature fluctuations and vibrations which could affect measurement accuracy. Use predictive modeling techniques powered by AI to automatically compensate for these variables in real time.

**Advanced Techniques & Reminder for Exploration**

If you're looking to take things one step further, consider delving into adaptive optics technologies or exploring machine learning applications tailored specifically for optical alignment processes. If you still have energy after implementing these steps, experimenting with different configurations might yield even more precise results over time!

By following this guide through each practical step, you'll not only enhance operational efficiency but also elevate the overall performance of your optics laboratory into new heights of precision and reliability!

The Future of Precision Machinery in Optics: What Lies Ahead?

Conclusion: Optimizing Your Optics Laboratory with Precision Tools

As we look ahead, it’s essential to consider how we can adapt our practices to stay at the forefront of this innovation. Embracing these advanced technologies will not only minimize downtime but also streamline resource allocation and improve overall productivity. The opportunity for optimization is vast, and now is the time to take action—explore whether implementing AI-driven solutions aligns with your laboratory's needs and goals.

Don't wait for issues to arise; anticipate them with predictive analytics. Let’s harness these advancements together and drive our optics labs toward greater efficiency and success!

Reference Articles

Optical precision machinery

High precision vibration isolation platform · High-performance optical frames ... lab laser system laser beam laser output laser spot PM Fiber laser UV laser ...

Source: TaorLabLaboratory Equipment - DahYoung Vacuum Equipment Co., Ltd.

High-performance coating with hardness, especially suitable for precision cutting tools, biomedical equipment, auto parts and other industries.

Official Launch of the NARLabs “Joint Research Laboratory for Ultra- ...

These teams come from a wide variety of disciplines ranging from ultra-precision machining technology and precision mechanical design to optical ...

Source: 國家實驗研究院Precision Module and Equipment Laboratory

Precision Optics Engineering Laboratory focuses on the research and development of diffractive optical technologies.

precision optical instruments laboratory

Rehabilitation Therapy · Precision instrument placement platform has excellent vibration isolation effect and is suitable for all optical laboratories.

Source: Alibaba.com2024 Optical Testing Equipment

... High Quality Quadratic Measuring Machine / Test Machine / Test Chamber / Testing Equipment by China manufacturer – Dongguan Kexun Precision Instrument Co., Ltd.

Precision Optics Manufacturing

The Precision Optics Laboratory is a manufacturer of optical and micro-optical components and sub-systems used in a wide range of applications.

Source: Durham UniversityOptics Lab Supplies

Newport offers a full range of lab supplies enabling experimental and industrial set-ups with our opto-mechanics products.

Source: Newport Corporation

ALL

ALL Precision Machinery

Precision Machinery

Related Discussions