Summary

This article explores the powerful partnership between precision machinery and 3D printing services, highlighting how their integration is revolutionizing manufacturing. Key Points:

- Generative design software optimizes part designs for both additive and subtractive manufacturing, resulting in lighter and stronger components.

- Multi-material hybrid manufacturing techniques are emerging, allowing different materials to be seamlessly integrated within a single part for enhanced performance.

- AI-driven quality control ensures real-time monitoring of production processes, minimizing downtime and improving efficiency.

Is Precision Engineering Reaching its Limits? The Promise of 3D Printing

My First 3D Printed Part: A Story of Initial Frustration and Unexpected Success

Day three rolled around, and after what felt like the hundredth recalibration, I hesitated before hitting 'print' again. My heart raced as layers began to form for what seemed like an eternity—two hours ticking away on the clock. Then it happened: a successful print! It wasn’t just any success; it felt monumental against the backdrop of my earlier flops. My colleague peeked over and said with surprise, “Hey, you did it!”

In that moment, we both paused—caught between disbelief and triumph—as if we’d stumbled upon some hidden treasure amid our struggles.

| Service Type | Description | Benefits | Latest Trends | Expert Insights |

|---|---|---|---|---|

| 3D Printing Services | Initial printing to post-processing using advanced technologies. | Rapid prototyping and design flexibility. | Growing integration with AI for design optimization. | Experts suggest leveraging generative design in 3D printing. |

| CNC Machining | Precision machining services for various materials, ensuring tight tolerances. | High accuracy and repeatability for functional parts. | Increased use of automation in CNC processes for efficiency. | Industry leaders recommend adopting IoT-enabled CNC machines for better monitoring. |

| Base Processing | Preparation of models before the final production stage. | Ensures quality and adherence to specifications. | Shift towards sustainable materials during base processing stages. | Consultants advise on eco-friendly material sourcing. |

| Post-Processing for 3D Printing | Finishing techniques to enhance the surface quality and functionality of printed parts. | Improves aesthetics and mechanical properties of parts. | Emerging trends include smart coatings that enhance durability. | Experts emphasize the importance of post-processing in achieving end-use requirements. |

| Facilities Expansion | Upgraded facilities offering quicker access to manufacturing technologies. | Shortens lead times and boosts production capabilities. | Trend towards establishing local manufacturing hubs to reduce shipping times. | Analysts highlight the strategic advantage of localized supply chains. |

From Failure to Functional: Overcoming the Hurdles of 3D Printing in Precision Machinery

Around me, my colleagues reacted differently. Some began rifling through manuals and old notes as if searching for answers hidden in the pages—frantically flipping them open while others simply sat back in their chairs, staring blankly at the ceiling as if trying to find inspiration in the patterns of the tiles above. We all felt it—the weight of expectations pressing down harder with each failed attempt.

I could hear one colleague muttering under his breath about deadlines creeping closer; another sighed loudly enough that we all turned our heads to look at him, his face an unreadable mix of frustration and concern. None of us wanted to admit how much this was starting to affect our morale—how doubts crept into our minds when they should have been focused on solutions. And just like that, the air felt thick with unspoken worry… then silence fell again like a curtain closing on hope.

How We Partner with Clients to Bridge the Gap Between Design and Reality Using 3D Printing Services

In one meeting, a client expressed his growing frustration: “We tried your initial suggestions, but they didn’t align with my vision.” This led to heated discussions about design iterations that left many feeling stuck. Despite attempts at new approaches—like integrating different 3D printing techniques—results remained inconsistent.

“It's like we're running in circles,” someone muttered under their breath. As deadlines loomed closer, there was palpable tension; some felt hopeful about potential solutions while others harbored doubts. Yet amid this turmoil, no one could say for sure whether our next steps would bring us any closer to success or simply deepen the quagmire of uncertainty.

Free Images

Free ImagesFrequently Asked Questions: Addressing Your Concerns About 3D Printing for Precision Parts

You might not realize this, but generative design isn’t just about creating a model; it involves sophisticated algorithms that explore countless design variations based on specific performance criteria. For example, if you need a part that balances strength and weight effectively, these tools can help optimize the geometry before any material is even touched. This means you end up with parts that are not only precisely manufactured through methods like laser powder bed fusion (LPBF) but are also tailored for their intended use. 💡 A little tip here: this optimization could lead to reducing material usage by up to 50%, which is not just cost-effective but also environmentally friendly!

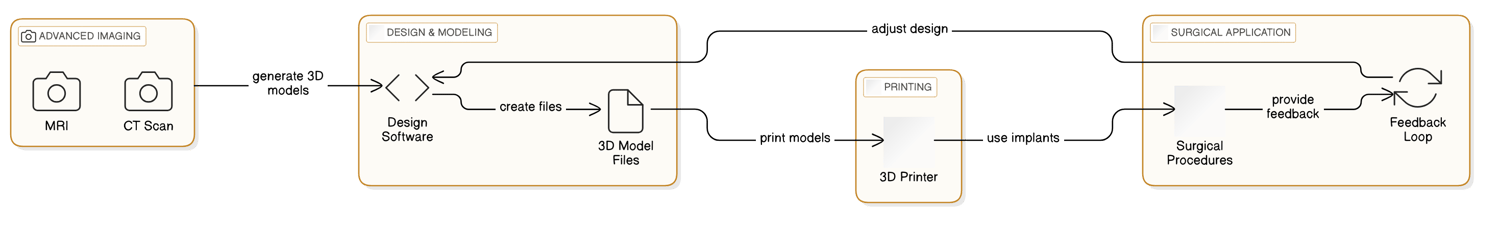

Another frequent concern revolves around the reliability of additive manufacturing processes. You might wonder whether these advanced techniques truly deliver consistent results over time. Here’s where the digital thread comes into play! By integrating every stage—from generative design through print parameter optimization to quality control—you gain superior traceability and data analysis capabilities. This continuous improvement loop helps ensure each batch of parts meets your exacting standards.

So yes, while it's natural to have questions about the effectiveness of 3D printing for precision applications, innovations like generative design are transforming how we approach manufacturing challenges—making it smarter and more efficient than ever before!

Beyond Prototypes: Can 3D Printing Services Truly Replace Traditional Machining?

The Debate: Is 3D Printing a Threat or an Enhancement to Precision Machinery Manufacturing?

A Practical Guide: Choosing the Right 3D Printing Service for Your Precision Engineering Needs

In today's fast-evolving manufacturing landscape, integrating 3D printing with precision machining offers unparalleled advantages. By harnessing this powerful partnership, engineers can achieve designs that were once deemed impossible, enhancing both efficiency and innovation. I highly recommend exploring these steps to select the right 3D printing service tailored to your precision engineering requirements.

Many professionals often overlook how critical it is to align their project needs with the capabilities of a 3D printing service provider. I remember when I first delved into this realm; I was surprised by how much my choice of service impacted not only production time but also the final quality of components.

Here’s a step-by-step guide to help you navigate this process effectively:

**Step 1: Define Your Project Requirements**

Start by clearly outlining the functional specifications of your project. Consider factors like material properties, mechanical strength, weight constraints, and dimensional tolerances (aim for ±2µm or tighter if needed). Understanding these parameters will significantly streamline your selection process.

**Step 2: Research Potential Providers**

Look for companies that specialize in both additive manufacturing and precision machining. Websites should provide detailed information about their technologies (like generative design integration) and case studies demonstrating their capabilities in high-value applications such as aerospace or medical devices.

*Tip:* Create a comparison chart listing potential providers alongside key features they offer—this visual aid can be incredibly helpful!

**Step 3: Evaluate Their Design Capabilities**

Select providers that utilize advanced software for generative design. This capability allows them to optimize designs specifically for additive manufacturing, resulting in innovative solutions like lattice structures that reduce weight while maintaining strength.

*Personal Note:* I've found it beneficial to ask potential providers about their design iteration process during initial meetings—it reveals their commitment to optimization.

**Step 4: Request Prototypes or Samples**

Before committing fully, request prototypes or sample parts from shortlisted services. This hands-on evaluation allows you to assess print quality and functionality directly related to your specific use case.

*Fun Fact:* Many people don't realize that requesting samples can also lead to valuable insights regarding post-processing options available with each provider!

**Step 5: Discuss Post-Processing Techniques**

Precision machining often requires additional finishing processes after additive manufacturing is complete. Have discussions about how they handle post-processing tasks—be sure they have experience refining critical surfaces or features according to stringent tolerances.

### Advanced Tips:

If you're eager to elevate your projects further, consider exploring hybrid methods where both additive and subtractive techniques are used within one workflow—for example, starting with an optimized printed component before refining it through CNC machining could yield outstanding results.

Should you wish to deepen your understanding of generative design integration further or explore advanced materials suited for specific applications, many resources

The Future of Precision: What Innovations Will 3D Printing Unlock?

Conclusion: Embracing the Synergy of Precision Machinery and 3D Printing Services – A Call to Action

The question now becomes: how can your organization leverage this synergy? Whether it's through investing in advanced technologies or refining existing workflows, there are numerous avenues to explore. Collaboration across disciplines can lead to breakthroughs that drive competitive advantage and open new markets.

Now is the time to take action—evaluate your current operations, identify areas where you can integrate precision machining with 3D printing, and embark on a journey towards enhanced productivity and innovation. Don’t wait for competitors to seize this opportunity; be proactive in shaping the future of your manufacturing landscape!

Reference Articles

Metal 3D printing / Contract manufacturing service

We offer one-stop services through the entire process including the secondary processing, from initial printing to super-fine ...

Source: 東レ・プレシジョンPrecision Machining of 3D Designs

Part of Vortex Group · Led by a team of expert machinists and CAD designers · Highly experienced staff · CNC ...

Source: Vortex 3DFast & Precise Plastic 3D Printing Services

Norck is a technology-powered manufacturing leader specializing in CNC machining, 3D printing, ...

Source: NORCKAdditive-Subtractive Synergy-Products & Services-Shanghai ESU ...

We can also provide services including base processing, 3D printing post-processing, and precision machining. One stop service for additive manufacturing.

Source: 上海毅速3D-Printed Tool Holders Enhancing Machining Precision - Ziggzagg

Discover how advanced 3D printing technology is transforming machining with the development of a high-precision, ...

Source: ziggzagg.com3D Printing - HF Precision Machining

At HF Precision, our industrial 3D printing service guarantees precise and repeatable parts every time. We specialize in functional prototypes, intricate ...

Source: hzlmetal.com3D Printing Services | CNC Machining 3D Printing

Our recently expanded 3D printing facility and our CNC machines are just a phone call away, at 573-646-3996, from helping you with ...

Source: Roberson Machine CompanyHigh Performance Precision Machining Prototyping Plastic/POM ...

High Performance Precision Machining Prototyping Plastic/POM/Metal SLS 3D Printing Service. Purchase Qty. / FOB Price: Get ...

Source: Made-in-China.com

ALL

ALL Precision Machinery

Precision Machinery

Related Discussions