Summary

This article explores the latest advancements in heavy-duty linear guide rails, highlighting their importance in enhancing performance and efficiency across various industries. Key Points:

- Advanced materials such as high-strength aluminum and carbon fiber reinforced polymers enhance the load capacity and lifespan of heavy-duty linear guide rails.

- Closed-loop control systems with advanced sensors provide exceptional precision, making them ideal for demanding applications like machining and robotics.

- Modular designs allow for customization and easy upgrades, meeting diverse industry needs while promoting sustainability through lifecycle assessments.

What Makes a Heavy Duty Linear Guide Rail Truly `Heavy Duty`?

My First Heavy Duty Linear Guide Rail Project: A Story of Trial and Error

We dove into the installation anyway—after all, how hard could it be? But as soon as we laid them down, it hit us: they were misaligned by nearly 5 millimeters. "This isn’t going to work," I groaned. We spent the next few hours adjusting and readjusting but made no headway.

“Seriously? How did this happen?” Sam shook his head in disbelief while glancing at the specs again. “I thought you double-checked.” I couldn’t help but roll my eyes; this wasn’t what I had envisioned for our big debut project.

By day’s end, frustration hung thick in the air—we left feeling utterly defeated and questioning every decision we’d made up to that point. It was clear: things weren’t going according to plan—and honestly, I hadn’t expected it to be this tough.

| Criteria | Single-Rail System | Double-Rail System |

|---|---|---|

| Load Capacity | Suitable for lighter loads and compact designs. | Higher load capacity, suitable for heavy-duty applications. |

| Stability | Less stable under high lateral forces. | Increased stability, ideal for dynamic applications. |

| Installation Space | Requires less installation space. | Requires more installation space due to dual rails. |

| Maintenance Needs | Generally lower maintenance requirements. | May require more frequent maintenance due to complexity. |

| Environmental Considerations | Best suited for clean environments with minimal exposure to contaminants. | Can be designed for harsher environments with protective features. |

The Turning Point: Overcoming Challenges with Heavy Duty Linear Guide Rails

Sam furrowed his brow, leaning closer. “What do you mean?” he asked, voice low.

“I’ve just realized… our design specs don’t match what we actually received. We’re off by more than just those 5 millimeters.” My words hung there for a moment, and I could see anxiety ripple through the team. Some glanced at each other, while others simply stared at their notes as if they were about to reveal some hidden truth.

“Are we even going to be able to use these rails?” one of our engineers muttered under his breath. He shifted uncomfortably in his seat.

Silence fell over us; it felt like everyone was holding their breath. A few minutes passed—some began flipping through documents searching for answers, while others leaned back with arms crossed, gazing blankly at the ceiling tiles above as if seeking guidance from above.

Then came a soft sigh from Sam: “Let’s just contact the supplier and sort this out.” With that suggestion hanging in the air, hope flickered faintly amid uncertainty—but now we had no choice but to push forward together.

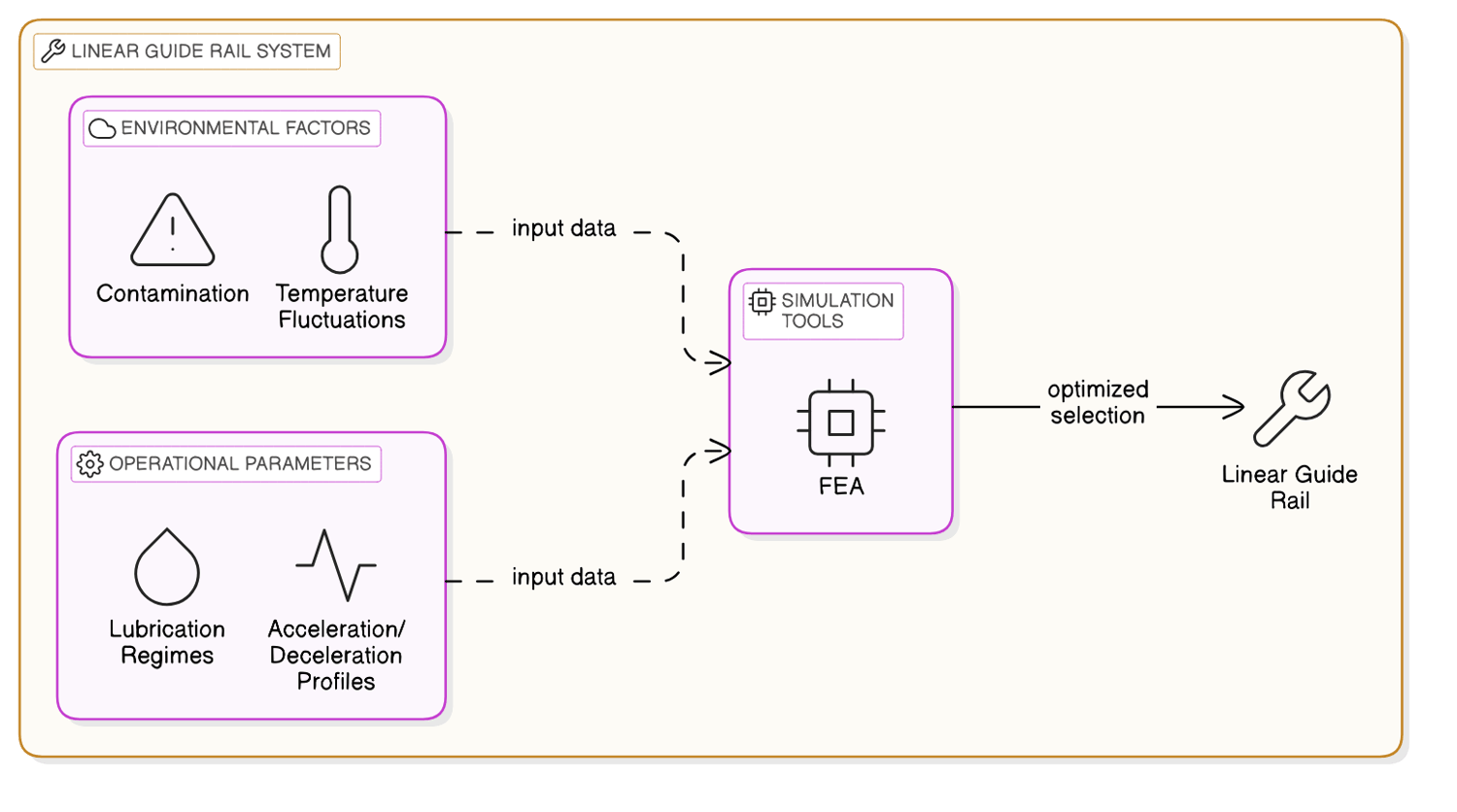

How We Help You Choose the Right Heavy Duty Linear Guide Rail System

“But what if their specs don’t meet our needs either?" Sarah countered, her voice tinged with skepticism. “We’ve been down that road before.”

The clock ticked loudly as they weighed their options. "It’s not just about finding rails; it's about ensuring they can handle the load," added Jason, frowning at his notes.

After some back-and-forth discussion over lunch, it was clear consensus was elusive. Some felt optimistic about reaching out to new vendors, while others worried about potential delays in the project timeline.

“Let’s draft a list of questions for them,” Mark proposed tentatively, but doubts lingered—would this really lead to a solution? No one could say for sure if it would truly work this time around.

Free Images

Free ImagesFrequently Asked Questions About Heavy Duty Linear Guide Rails

For instance, many people overlook the impact of using advanced materials like high-strength, low-friction ceramics—think silicon nitride—combined with traditional steel components. This hybrid approach not only enhances load capacity but also significantly boosts wear resistance. In fact, research shows that ceramic rollers can extend lifespan by reducing wear by 30-50% compared to regular steel rollers, especially under high loads and extreme conditions. 🌟

Imagine working in an environment where you're dealing with heavy impacts or abrasive elements; this improvement could mean the difference between frequent replacements and a more durable setup! Plus, surface treatments such as PVD (Physical Vapor Deposition) have taken things a step further by enhancing hardness and reducing friction even more.

So next time you consider which linear guide rail to choose for your application, remember: advancements in materials aren’t just buzzwords—they're vital for ensuring long-lasting performance! 💡

Beyond Load Capacity: What Other Factors Define a Superior Heavy Duty Linear Guide Rail?

The Price vs. Performance Dilemma: Are Premium Heavy Duty Linear Guide Rails Worth the Investment?

Practical Application: Case Studies of Heavy Duty Linear Guide Rail Implementation

In today’s rapidly evolving industrial landscape, the integration of IoT technology into heavy-duty linear guide rail systems is becoming a game-changer. This approach not only helps in minimizing unexpected downtimes but also optimizes maintenance schedules, ultimately leading to significant cost savings. I highly recommend exploring predictive maintenance as it has proven effective for many organizations and can transform your operational efficiency.

I remember when I first encountered this concept while working on an automated warehousing project. Many were skeptical about the upfront investment in IoT sensors; however, those who embraced it saw remarkable results—like a 30% reduction in unscheduled downtime! Here’s how you can implement this innovative solution step-by-step:

#### Step 1: Assess Your Current Setup

Evaluate your existing linear guide rail system to identify critical points where sensors could be deployed. Look at areas prone to wear and tear or high-stress zones. (Tip: Make a checklist of frequently monitored parameters like vibration, temperature, and lubrication levels.)

#### Step 2: Choose Appropriate Sensors

Select IoT sensors that fit your needs based on the parameters identified in Step 1. Ensure they are compatible with your existing systems and can communicate effectively with your central monitoring platform.

#### Step 3: Install Sensors

Carefully install the selected sensors at critical locations on the guide rails. Follow manufacturer guidelines for placement to ensure accurate readings. (Pro tip: Use mounting brackets that allow easy repositioning if necessary.)

#### Step 4: Set Up Data Collection

Integrate the sensors with a centralized data analytics platform capable of real-time data collection and processing. Make sure that all relevant personnel have access to this system for monitoring purposes.

#### Step 5: Implement Machine Learning Algorithms

Utilize machine learning algorithms within your analytics platform to analyze historical data alongside real-time sensor readings. This will help identify patterns indicative of potential failures before they happen.

#### Step 6: Establish Maintenance Protocols

Based on insights gained from predictive analytics, develop new maintenance protocols that prioritize actions based on urgency rather than fixed schedules.

### Advanced Tips for Enhanced Results

If you're looking to further refine your predictive maintenance strategy, consider establishing alerts within your monitoring system for when certain thresholds are exceeded—this proactive measure allows teams to address issues before they escalate into costly repairs or unplanned downtimes.

Should you wish to take it a step further, think about integrating augmented reality (AR) tools for remote troubleshooting guided by real-time data analysis; this can streamline repair processes even more efficiently!

By systematically following these steps, you’ll not only enhance the reliability of your heavy-duty linear guide rail systems but also gain peace of mind knowing you've taken significant strides toward operational excellence through innovation!

The Future of Heavy Duty Linear Guide Rails: What Innovations Lie Ahead?

Selecting Your Heavy Duty Linear Guide Rail: A Summary and Next Steps

Consider incorporating energy efficiency metrics, such as low-friction coatings and eco-friendly lubricants, which not only enhance performance but also reduce operational costs over time. Additionally, selecting materials that are recyclable—like aluminum alloys or sustainable steel compositions—can significantly impact both your project's environmental footprint and its overall lifecycle cost.

To navigate this evolving landscape effectively, leverage advanced software tools that allow you to model total cost of ownership (TCO) alongside traditional performance specifications. This holistic view will enable you to make informed choices that align with contemporary sustainability goals while ensuring optimal productivity in your applications.

Now is the time to take action: explore how these innovative approaches can fit within your operational framework and contribute positively to both your bottom line and the environment. How will you adapt to this emerging trend in heavy-duty linear guide rail selection?

Reference Articles

Linear Guides (Linear Motion Guides) Design and Selection

A linear guide is a machine element that utilizes bearings, which were developed for rotary motion, in order to move heavy objects easily in a straight line.

Source: THKHow To Choose The Best Linear Guide For Your Applications

This article will guide you on how to quickly choose the right linear guides for your smooth operation and applications!

Source: SLS BearingsLinear Guide Rails Selection – Where to start?

1.) Check what linear guide rails are used in similar machines · 2.) Assessment of the loads in your case · 3.) Evaluation of the load capacity of ...

Source: the Tuli shop4 steps to select your linear guide rail

A linear rail consists of a runner, with recirculation ball bearing or rollers, which slides inside a rail. This 4 steps guide help you in selecting THE linear ...

Source: ChambrelanHDS2 Heavy Duty Linear Guide System

Hepco's HDS2 heavy duty linear guide provide a low maintenance solution for applications with loads up to 68kN. Extensive choice of bearings and drive ...

Source: HepcoMotionLinear Guideways

Hiwin Corporation offers a variety of linear guideway series, each featuring different options for sizes, loading capacity, ...

Source: HIWINLinear Rail and Guides

Designed to support heavy loads and high dynamic forces, these linear guideway systems come in standard sizes ranging ...

Source: Kiwi Motion5 ways to Choose the Best Linear Guide for Your Application

1. Choose your materials: · 2. Check the bearing load capacity: · 3. Choose between a double-rail or single-rail system: · 4. Use ...

Source: igus

ALL

ALL Precision Machinery

Precision Machinery

Related Discussions