Summary

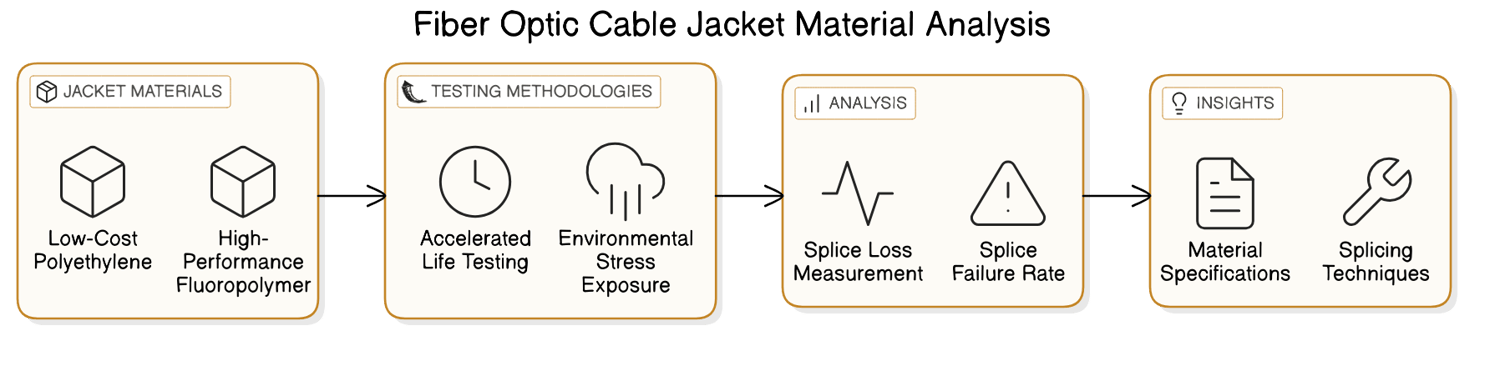

This article provides a comprehensive guide to mastering fiber splicing in precision machinery, highlighting its significance for professionals in the field. Key Points:

- Explore the evolution of fusion splicing techniques, including automated systems that utilize advanced algorithms for enhanced precision and speed.

- Analyze how emerging fiber optic cable designs challenge traditional splicing methods and require specialized equipment to maintain efficiency and performance.

- Delve into predictive maintenance strategies powered by AI, optimizing fiber splicer management through data-driven diagnostics.

Why Mastering the Fiber Splicer is Crucial for Precision Professionals?

My First Fiber Splice: A Tale of Trial and Error

He remembered how effortlessly his mentor had performed splices years ago; it felt like a distant memory now. Each failed attempt left him feeling more defeated—sweat dripped down his brow as tools lay scattered around him like crumpled hopes. “I can’t believe I’m messing this up,” Alex thought, shaking his head in disbelief.

At 5:30 PM, with tension mounting and self-doubt creeping in, he glanced around at the mess he'd created—a stark contrast to the flawless splices he'd witnessed before. Just then, a voice broke through his thoughts: “Hey Alex, you okay?” He paused; maybe it was time for a different approach after all...

| Splicing Method | Description | Advantages | Disadvantages | Common Applications |

|---|---|---|---|---|

| Fusion Splicing | Melding the ends of two fibers using heat. | Low signal loss, strong and durable join. | Requires expensive equipment and skilled technicians. | Long-distance telecommunications, data centers. |

| Mechanical Splicing | Aligning the fiber ends in a fixture and holding them together with an adhesive or optical gel. | Easier to perform, no need for expensive fusion splicer. | Higher signal loss compared to fusion splicing. | Temporary repairs, quick fixes in field installations. |

| V-Grooved Splicing | Using a V-shaped groove to hold the fibers in place during alignment and bonding. | Simple setup, good for different types of fibers. | Can be less reliable than fusion splices over time. | Fieldwork where speed is critical. |

| Post-Splice Testing | Verifying splice quality through optical time-domain reflectometer (OTDR) tests or insertion loss measurements. | Ensures optimal performance post-splice, identifies issues early. | Additional testing equipment needed can increase project costs. | Quality assurance in all fiber optic installations. |

The Turning Point: Overcoming My Initial Fiber Splicer Frustrations

Alex noticed one of his coworkers, Sarah, rifling through manuals with furrowed brows, while another guy leaned back in his chair, arms crossed tightly—an unmistakable sign of frustration. “This shouldn’t be taking this long,” he muttered under his breath, and Alex felt a pang of guilt. He didn’t want to drag them down with him.

He took another deep breath. The tools around him seemed to mock his struggle now more than ever; they lay there like silent judges critiquing every misaligned fiber attempt. The tension in the room was palpable—nobody dared to break the silence that filled the space like thick fog.

In that moment, it hit him: perhaps this wasn’t just about him anymore—it affected everyone around him too. But then again… maybe he could turn things around before it got any worse?

How We Guide Professionals to Fiber Splicing Success

Tension filled the air as voices rose and fell like a tide—some believed they were on the brink of a breakthrough while others remained skeptical. “Surely there’s gotta be a simpler way,” Alex said hopefully. Yet as they attempted the new approach, mistakes persisted despite their efforts. With time ticking away and doubts creeping in, no one could say for certain if this latest attempt would lead them to success or further frustration.

Free Images

Free ImagesFrequently Asked Questions: Demystifying the Fiber Splicer

💡 Here’s a little tip: integrating AI-assisted analysis into your process can significantly enhance the precision of your assessments. This technology goes beyond what we can see – it analyzes microscopic images of the cleaved fiber endface and provides quantitative metrics for things like angle deviation and surface roughness (Ra).

For instance, a colleague of mine was experiencing higher than usual splice losses. After adopting an AI-powered system for quality control, he discovered subtle discrepancies in his cleaving technique that he had previously overlooked. Now, with real-time data analysis at his fingertips, he's able to proactively address potential issues before they escalate.

So if you're striving for lower insertion losses (ideally below 0.02dB!) and better repeatability in your splices, consider embracing these advanced technologies. It not only streamlines maintenance but also minimizes costly rework—saving you time and resources in the long run!

Beyond the Basics: Exploring Advanced Fiber Splicing Techniques?

The Challenges of Precision: Addressing Common Fiber Splicing Hurdles?

Step-by-Step Guide: Mastering the Art of Fiber Splicing

When it comes to fiber splicing, particularly in today's high-demand environments like 5G networks and data centers, precision is everything. I highly recommend exploring active alignment fusion splicing techniques as they significantly enhance splice quality and network performance. Having navigated through various methods myself, I've learned that adopting these steps can make a world of difference—especially for those new to this technology.

Many professionals often overlook the advantages of using active alignment systems, thinking traditional visual alignment suffices. However, I once faced challenges with splice loss that could have been easily avoided by implementing these advanced techniques. With that said, let's dive into the step-by-step process of mastering fiber splicing with active alignment.

#### Step 1: Set Up Your Active Alignment Fusion Splicer

- **Tools Needed**: Active alignment fusion splicer, power supply, cleaning tools (isopropyl alcohol wipes).

- Begin by placing your fusion splicer on a stable surface in a clean environment. Ensure it’s powered on and fully charged.

- **Tip**: Spend a few extra moments cleaning your workspace; it prevents contamination during critical processes.

#### Step 2: Calibrate the System

- Follow the manufacturer's instructions to initiate calibration procedures.

- During this phase, ensure all cameras are clean and adjust settings as necessary for optimal performance.

- **Note**: Calibration is crucial; any misalignment at this stage can lead to higher splice losses later on.

#### Step 3: Prepare Fiber Ends

- Use appropriate stripping tools to remove insulation from the optical fibers without damaging them.

- Clean both ends thoroughly using isopropyl alcohol wipes until no residue remains visible.

- **Personal Habit**: I always double-check my work here—clean fibers mean better results!

#### Step 4: Insert Fibers into Splicer

- Carefully insert each prepared fiber end into their designated ports in the fusion splicer.

- Make sure they are seated properly; improper seating can lead to inaccurate measurements during splicing.

#### Step 5: Monitor Camera Feedback

- Once fibers are inserted, monitor real-time camera feedback from the system’s display.

- Adjust positioning based on algorithmic suggestions provided by your splicer's software—it’ll guide you toward achieving lower splice loss levels (aim for below 0.05dB).

#### Step 6: Execute Fusion Splice

- Once satisfied with alignments based on camera feedback, initiate the fusion process via your device's control panel.

- Watch closely; this moment determines splice quality!

#### Advanced Techniques:

After completing basic procedures successfully, consider experimenting with different types of connectors or configurations tailored for specific applications. If you're looking to push further into advanced techniques like optimizing splice parameters based on environmental conditions or utilizing automated documentation features within your equipment—go for it! Every bit of knowledge gained will only bolster your efficiency and expertise.

Remember, every professional starts somewhere; don't hesitate if you find yourself needing more practice or resources along the way!

What`s Next in Fiber Splicing Technology: Future Trends?

Conclusion: Embrace Precision and Elevate Your Fiber Splicing Skills

This trend isn't just a passing phase; it represents a fundamental transformation in how we approach fiber splicing. Embracing these innovations requires an open mindset and a willingness to learn new techniques that can elevate your expertise. By integrating automation into your workflow, you position yourself not only as a skilled technician but also as a forward-thinking professional capable of maximizing network performance.

So why wait? Take the initiative today to explore automated solutions and assess how they can fit into your current practices. The future of fiber splicing is bright—let's embrace this change together and elevate our skills to meet the demands of tomorrow!

Reference Articles

The Ultimate Guide to Splicing of Fiber: Techniques and Tips

There are two primary methods for splicing fiber optics: fusion splicing and mechanical splicing. Fusion splicing melds the ends of fibers ...

Source: Phoenix CommunicationsSplicing Fiber Optic Cables | A Beginner's Guide

Fusion splicing is the most used method of fiber optic splicing and the main one we will discuss. Rather than using a cover to align the ...

Source: Advanced Test Equipment Corp.Fiber Optic Splicing Explained

Fiber optic splicing is used to join two fiber optic cables together. This is most commonly done when a cable is accidentally severed.

Source: adbcompaniesSplicing of Optical Fibers : Techniques, Advantages & Disadvantages

They are fusion splicing and mechanical splicing. The mechanical splicing is again divided into two types such as V-grooved splicing and ...

Source: ElProCusFiber Optic Cable Splicing Explained

Splicing in optical fiber is the joining two fiber optic cables together. There are 2 methods of cable splicing, mechanical or fusion.

Source: Fiber Optic CenterFiber Optic Splicing: Fusion Splicing in 6 Simple Steps!

Step 1: Preparation · Step 2: Fiber Stripping · Step 3: Fiber Cleaving · Step 4: Fusion Splicing · Step 5: Splice Protection · Step 6: Post-Splice ...

Source: LinkedInDifferent types of Fiber Splicing

Typically, we can undertaken fiber optic splices two ways: fusion splicing and mechanical splicing. Fusion splicing Method. Fusion splicing is the process by ...

Steps of Fusion Splicing Fiber Optic Cables - Samm Teknoloji

1. Insert One Side of Fiber in the Splice Protective Sleeve. · 2. Strip the Fibers' Buffer Coatings Accurately. · 3.

Source: Samm Teknoloji

ALL

ALL Precision Machinery

Precision Machinery

Related Discussions