Summary

This article explores essential considerations for selecting the best 3D printer parts to elevate your printing experience, emphasizing their importance in achieving high-quality outputs. Key Points:

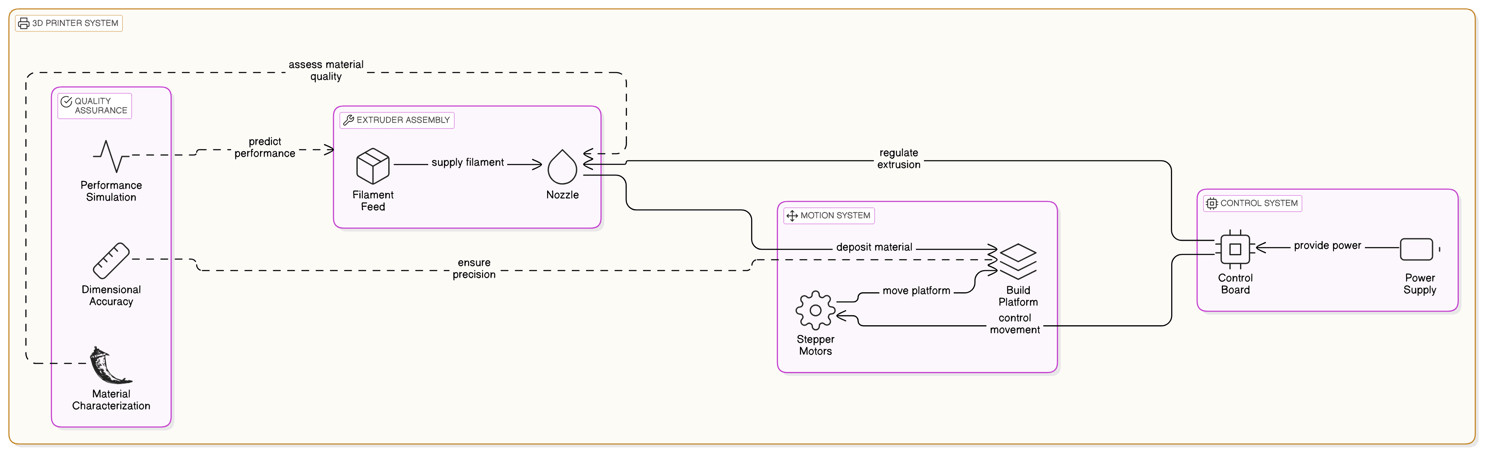

- Tight manufacturing tolerances in 3D printer parts greatly enhance print precision and repeatability, affecting layer adhesion and overall quality.

- AI-driven predictive maintenance helps identify potential failures before they occur, promoting proactive replacement of components and minimizing downtime.

- The trend towards biocompatible and sustainable materials addresses the growing demands of biomedical applications while fostering eco-friendly practices.

Ready to Unleash Your 3D Printer`s Full Potential?

My First 3D Print: A Hilarious (and Slightly Frustrating) Tale

By noon, he’d already spent two hours troubleshooting online forums filled with cryptic advice like "ensure proper bed leveling" and "check the nozzle temperature." “Seriously? This feels more like rocket science,” Alex sighed while trying to decipher the jargon.

His second try ended in a tangled mess of plastic spaghetti that looked nothing like the sleek design on his computer screen. “Why won’t it stick?” he groaned, eyeing the failed print pieces scattered across his desk.

At 4 PM, frustration hit a peak when strange grinding noises echoed from the printer—a sound that made him question if this whole venture was worth it. “Is this even normal?” He glanced at his phone for answers again but only found more questions. At that moment, staring at a pile of failures felt daunting; maybe 3D printing wasn’t meant for him after all.

| Part Type | Description | Benefits | Trend |

|---|---|---|---|

| Nozzles | Different sizes and materials available for various filament types. | Improves extrusion control and print quality. | Increasing use of hardened nozzles for abrasive filaments. |

| Hotends | Designed to handle high temperatures and different filament viscosities. | Allows for a wider range of materials, including specialty filaments. | Growing popularity of all-metal hotends for high-temperature printing. |

| Extruders | Gear-driven or direct-drive systems that improve filament feeding. | Enhances consistency in material flow, reducing clogs and jams. | Shift towards lightweight extruders for faster prints without sacrificing quality. |

| Spool Holders | Organize filament spools to reduce tangling during printing. | Ensures smooth feeding of filament into the printer. | Innovative designs allowing dual spool setups are gaining traction. |

| Camera Mounts | Stabilizes cameras for real-time monitoring of print jobs. | Enables users to oversee print progress remotely, enhancing convenience. | Integration with IoT devices for automated alerts on print status is trending. |

The Turning Point: When My 3D Prints Finally Started Looking Good

Alex shrugged, feeling the weight of their expectations. “I thought I had it all figured out,” he muttered under his breath. Some of his friends began flipping through manuals and online guides on their phones—others just stared blankly at the printer as if willing it to work.

“Maybe we should take a break?” suggested Mia quietly, her eyes darting between Alex's frustrated face and the sputtering machine. There was an unspoken understanding in the air; everyone felt something was off but couldn’t quite put their fingers on it.

Then came a loud crack from the printer—a sharp reminder that this wasn’t going smoothly at all. “What now?” Alex groaned as he threw up his hands in despair. A few deep breaths later, he knew he needed clarity before anyone else lost hope too.

How We Helped a Fellow Maker Solve Their 3D Printing Woes

After an hour of back-and-forth troubleshooting, Alex's printer finally produced a semi-successful print but not without its flaws. “It’s better than before, but still not perfect,” he noted with a hint of disappointment. The atmosphere was mixed; some felt optimistic while others remained cautious about the long-term fix. As they mulled over their next steps, uncertainty loomed—could this really be the turning point or just another temporary band-aid?

Free Images

Free ImagesTop 5 FAQs About Choosing the Right 3D Printer Parts

Beyond the Basics: What Other 3D Printer Parts Should I Consider?

The Great Debate: Quality vs. Cost – Finding the Sweet Spot for Your 3D Printer Parts

A Practical Guide: Selecting the Best Nozzles, Beds, and Filaments for Your Projects

When it comes to optimizing your 3D printing experience, choosing the right components is crucial. I’ve found that many enthusiasts overlook the importance of pairing high-temperature nozzles with advanced filaments like PEEK or ULTEM. This combination can significantly enhance your print quality and material performance but requires careful attention to detail.

I remember when I first experimented with a high-temperature nozzle; initially, I faced challenges with warping and layer adhesion. However, after refining my approach—particularly by controlling temperature profiles—I was able to achieve remarkable results. Here’s how you can do it too:

#### Step-by-Step Guide to Optimize Your 3D Printing Setup

1. **Select Your Nozzle:**

- Choose a hardened steel or ruby nozzle rated for temperatures exceeding 300°C.

- **Tip:** Ensure that your printer's hotend can handle these temperatures.

2. **Choose the Right Filament:**

- Opt for advanced thermoplastics such as PEEK, PEI, or ULTEM.

- **Note:** Each filament has specific requirements; always check the manufacturer's recommendations.

3. **Calibrate Your Extrusion Temperature:**

- Set your extrusion temperature within +/- 5°C of what’s recommended on the filament spool.

- **Personal Habit:** I set a timer during this step ⏱️ to ensure I don’t forget about monitoring adjustments!

4. **Prepare Your Print Bed:**

- Use specialized bed materials like PEI sheets or borosilicate glass combined with appropriate adhesives.

- Adjust the bed temperature based on the filament type; typically between 60°C and 120°C works well depending on the material.

5. **Monitor Ambient Conditions:**

- Keep an eye on room temperature and humidity levels as they greatly influence print success.

- If possible, use an enclosure around your printer to maintain consistent conditions.

6. **Test Prints for Fine-Tuning:**

- Start with small test prints before moving onto larger projects to refine settings further.

- Make adjustments based on observations regarding warping and layer adhesion—this is where patience pays off!

#### Advanced Techniques and Considerations

If you're looking to take things further in optimizing your setup, consider experimenting with dual-material printing if your hardware allows it—this opens doors for even more complex designs! Additionally, keep in mind that using different bed surfaces may yield varying results with each filament type.

Should you encounter issues like inconsistent layer adhesion, revisit those temperature settings again—it might just be a matter of tiny tweaks leading to major improvements! Remember, every machine behaves slightly differently; embrace some trial-and-error as part of your journey toward mastering high-performance printing techniques!

What`s Next in 3D Printing Technology? Exploring Future Innovations in Parts

Level Up Your 3D Printing: A Summary and Actionable Steps

As we explore the landscape of modern 3D printing, it's clear that traditional methods of calibration are being revolutionized by AI-powered print optimization. This shift represents a significant advancement beyond merely upgrading hardware components; it introduces a realm where intelligent algorithms enhance our printing experience in real-time.

Imagine a scenario where your printer can autonomously analyze its performance, detect potential issues like nozzle clogs or material warping during the print process, and make instant adjustments to settings such as temperature and speed. Companies like Prusa Research are leading this charge with innovations in their slicer software, allowing users to focus more on creativity rather than troubleshooting.

This trend isn't merely a passing phase; it signals an evolution in how we approach 3D printing. As these technologies continue to mature, they will redefine the benchmarks for print quality and reliability—making high-quality outcomes less reliant on individual skill sets and more about leveraging advanced predictive capabilities.

So, what does this mean for you as a 3D printing enthusiast? It's time to embrace these advancements wholeheartedly. Start experimenting with AI-enhanced slicing software and stay informed about new features that can take your prints to the next level. The possibilities are vast, and those willing to adapt will undoubtedly find themselves at the forefront of this exciting transformation. Now is the moment to take action—explore these innovations today and see how they can elevate your own 3D printing journey!

Reference Articles

3D Printer Parts - Upgrades & Spare Parts

We have a wide range of 3D FDM Printer Parts, 3D Resin Printer parts and SLS 3D Printer Parts. We offer nozzles, cables, ...

Source: Ultimate 3D Printing StoreDoes anybody 3d print there parts? Want advice on what printer to buy.

I've been running 3d printed skids, chassis braces, link risers, servo & winch mounts for quite awhile. Self printed and bought. All holding up very well.

Source: RedditBest 3D Printer Parts & Accessories

Discover the best 3D Printer Parts & Accessories in Best Sellers. Find the top 100 most popular items in Amazon Industrial & Scientific Best Sellers.

Source: Amazon.com3D Printer Parts

Make your 3D Printer into the best 3D printer it can be with these 3D printer upgrade parts such as the best 3D printer hotend and 3D printer extruder upgrades.

Source: MatterHackersOther Printer Parts & Upgrades | 3D Printers | 3D models

Customize your 3D printer with hundreds of enhancements! Download spool holders, camera mounts, LCD covers, fan shrouds and even the Lack enclosure!

Source: Printables.com3D Printer Spare Parts and Upgrades - 3DJake International

We have numerous 3D printer upgrades and spare parts and we will definitely find the right one for you!

Source: 3DJakeSpare Parts & Upgrades

Spare Parts and Upgrades for 3D Printers. We offer a wide selection of parts to keep your 3d printers running as well as ...

Source: 3D Printer Superstore3D Printer Parts: The Top 10 Stores Online

Whether parts on your 3D printer break or you just want an upgrade, check out our picks for the best online ...

Source: All3DP

ALL

ALL Precision Machinery

Precision Machinery

Related Discussions