Summary

This article delves into the critical aspects of static loading in precision machinery, emphasizing its significance for engineers aiming to enhance performance and reliability. Key Points:

- Advanced material characterization techniques like Digital Image Correlation (DIC) and in-situ diffraction are essential for understanding microstructural changes under static load, leading to better predictions of machinery component behavior.

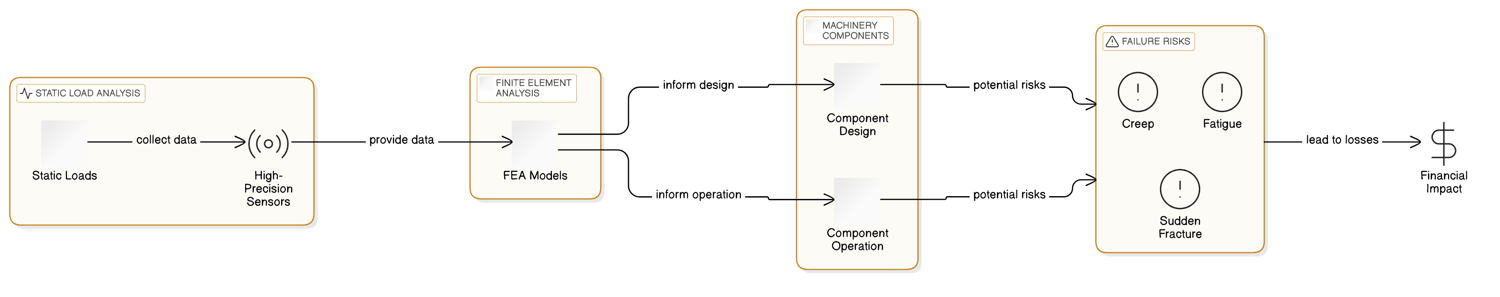

- Integrating Finite Element Analysis (FEA) with thermal effects and fatigue allows for accurate simulations of complex interactions, enhancing the understanding of non-linear material behavior under static loads.

- AI-driven predictive maintenance using real-time static load monitoring helps identify potential failures early, optimizing maintenance schedules and reducing downtime.

What Happens When Precision Machinery Meets Static Loading?

My First Static Load Test: A Tale of Unexpected Failures

As the clock ticked closer to ten, anticipation filled the air. But when the weight hit just 350 kg—a deafening crack shattered their hopes. “What just happened?” Jamie gasped, eyes wide in disbelief.

“I didn’t think it would fail so soon!” Alex muttered, staring at the broken piece as if it held all the answers. The numbers danced mockingly in their mind; how could they miscalculate so drastically? Everyone felt a mix of shock and frustration—it wasn’t just about failure; it was about understanding why it happened at all. In that moment of stunned silence, questions loomed larger than ever before—what had they missed?

| Key Features | Static Load Distribution Model | Ultraprecision Processing Technology | Impact on Structural Performance | Optimization Techniques |

|---|---|---|---|---|

| High Accuracy & Low Rumble | Incorporates Geometric Errors in DNBS Systems | Guides Advanced Machine Tool Design | Influences Load Capacity and Machining Quality | Helps Balance Cost, Weight, and Performance |

| Geometric Error Considerations | Improves Predictability in Static Loads | Enables Complex Geometries in Components | Enhances Reliability of Precision Machinery | Facilitates Lightweight Designs Without Compromising Strength |

| Design Implications for Engineers | Essential for Ensuring Stability Under Load Conditions | Promotes Innovation in Manufacturing Processes | Critical for Achieving High Tolerance Levels in Production | Aids in Developing Sustainable Engineering Solutions |

| Latest Trends in Precision Engineering | Adoption of AI and Machine Learning for Predictive Maintenance | Integration of Smart Technologies for Real-Time Monitoring | Emerging Materials to Enhance Durability and Efficiency | Focus on Sustainability and Energy-Efficient Practices |

The Turning Point: Identifying the Root Cause of Static Load Issues

“Did we really miss something this big?” Jamie asked, glancing around at the faces of their colleagues. Some furrowed their brows in thought; others stared blankly at the floor. A couple of team members started flipping through manuals and specifications as if expecting to find an answer hidden among the pages.

“I mean… we all thought 400 MPa was safe,” Alex replied slowly, feeling a knot tighten in their stomach. “But now I’m questioning everything.”

The air felt heavy, almost stifling. One engineer shifted nervously in his chair while another scratched notes on her pad but didn’t seem to register what she was writing anymore. “Maybe it’s not just about numbers? We should look into how these were manufactured…” Jamie suggested hesitantly, trailing off as they both realized the implications of overlooking such details.

Nobody spoke for a moment; it was as if everyone was holding their breath. Then someone finally broke the silence: “So… what do we do next?”

Our Approach: Diagnosing and Solving Static Load Problems in Precision Machinery

One engineer chimed in, “But what if the design is at fault? We can’t ignore that.” A murmur of agreement rippled through the group, but another member shook their head, saying, “Testing materials might just delay us further; we need a holistic approach.”

As they debated next steps over scattered blueprints and data sheets, it was clear that consensus was elusive. Amidst rising tension and conflicting opinions about potential solutions, uncertainty hung heavily in the air: could they uncover the root cause before time ran out?

Free Images

Free ImagesFrequently Asked Questions about Static Loading in Precision Equipment

💡 A little tip: Many overlook how crucial this concept is during design and maintenance phases. For instance, manufacturers of high-precision robotic arms might not consider the long-term effects of static loads until they start seeing signs of wear or fatigue. By integrating advanced technologies like digital twins with traditional finite element analysis (FEA), we can gain real-time insights into how these loads impact performance over time.

Another frequent question I hear is, "What should I do if my equipment shows signs of strain?" This is a situation where proactive measures are vital! Instead of waiting for issues to arise, using predictive maintenance strategies powered by digital twin technology can help you anticipate problems before they escalate. This way, you’re not just reacting; you're preparing and optimizing your operations based on actual data.

Lastly, many wonder about the limitations of traditional methods for handling static load analysis. It's true—while FEA provides a foundation for understanding stresses within materials, it doesn't account for every variable present in real-world conditions. That’s why embracing newer technologies can significantly enhance your analytical capabilities and lead to better decision-making in maintaining precision machinery.

In summary, understanding static loading isn't just about knowing what it is; it's about recognizing its implications and leveraging modern tools to stay ahead!

Beyond the Basics: Understanding Different Types of Static Loads and Their Impact

The Static Load Conundrum: Balancing Rigidity and Flexibility in Design?

Practical Steps: Implementing Effective Static Load Mitigation Strategies

When it comes to precision machinery, understanding and addressing static loading is crucial for optimal performance and longevity. I recommend these steps because they not only help you anticipate potential failures but also enhance the overall design process. Many professionals underestimate the importance of proactive strategies, often waiting until after a failure occurs to address issues related to static loads.

I once encountered a situation where our team faced significant downtime due to unexpected static load failures in one of our key machines. It was an eye-opener that reinforced the need for a forward-thinking approach in our designs. Here’s how you can implement effective static load mitigation strategies using AI-driven Finite Element Analysis (FEA).

#### Step-by-Step Guide

1. **Define Your Requirements**

- Begin by clearly defining the expected loads on your machinery components based on operational conditions.

- Reference parameters like maximum operating loads, environmental factors, and usage frequency can guide this process.

2. **Select Appropriate Software Tools**

- Choose advanced FEA software that integrates AI capabilities for generative design (e.g., ANSYS or Autodesk Fusion 360).

- These tools will allow you to simulate various material behaviors under different load conditions effectively.

3. **Gather Material Data**

- Compile data regarding material properties such as yield strength, Young's modulus, and Poisson's ratio for potential materials (like advanced stainless steels or titanium alloys).

- This step ensures you have reliable information when setting up your simulations.

4. **Run Initial Simulations**

- Input your geometric designs into the FEA software and run preliminary simulations.

- Pay attention to stress concentrations and deflection patterns; this is where many designs may reveal weaknesses.

5. **Optimize Designs Using AI-Driven Insights**

- Utilize generative design features within the software that allow AI algorithms to suggest alternative geometries based on initial results.

- You might be surprised at how minor adjustments can lead to major improvements in resistance against static loads!

6. **Evaluate Safety Factors**

- Ensure your final designs include safety factors—aim for configurations that exceed a pre-defined threshold (e.g., 2.5x predicted maximum load).

- This precaution helps avoid catastrophic failures down the line.

7. **Finalize Design & Document Findings**

- Once satisfied with your optimized design, finalize it while documenting all findings from your simulation processes.

- Keeping thorough records can aid future projects and provide insights into decision-making processes.

#### Advanced Tips

If you're looking for more ways to enhance your approach further or tackle specific challenges you've encountered during implementation:

- Consider integrating real-time monitoring systems post-deployment which continuously assess component stresses during operation.

- If time permits, explore additional optimization techniques such as topology optimization which could yield even lighter yet stronger components without sacrificing performance.

By proactively employing these strategies in precision machinery design using AI-driven FEA, you'll significantly reduce risks associated with static loading while ensuring greater efficiency in both production costs and material utilization—ultimately leading towards smarter engineering solutions!

The Future of Static Load Management: What Challenges Lie Ahead?

Conclusion: Mastering Static Loads for Enhanced Precision Machinery Performance

This trend towards advanced modeling techniques not only allows us to predict structural behavior more accurately but also equips us with the tools to anticipate and mitigate potential failure mechanisms. With ongoing research validating these approaches through experimental methods like digital image correlation, we are on the brink of redefining standards in precision machinery.

Now is the time to take action—explore how you can implement these advanced strategies into your own projects! Adapting to this evolving landscape will ensure that you remain at the forefront of precision engineering, ready to tackle challenges with confidence and creativity.

Reference Articles

High precision machine design principles

6. Bearings: high accuracy; high averaging/low rumble; low thermal effects; low limiting friction; high damping.

Source: 國立臺灣大學Principles and Techniques for Designing Precision Machines

The main theme of this thesis is machine design using fundamental precision- engineering principles. Design is such a huge topic that several recent books on ...

Source: OSTI.GOV (.gov)Static load distribution and axial static contact stiffness of a preloaded ...

We propose a static load distribution (SLD) model of a preloaded DNBS considering geometric errors, which takes into account the influence of non-loaded balls.

Source: ScienceDirect.comStructure Design of Precision Machines

This chapter starts with the ultraprecision processing technology and then analyzes the route of ultraprecision machine tools' forward design.

Source: SpringerSystem for materials testing at static loading

In modern laboratories universal testing machines with servo-controlled loading mechanisms are used for conducting mechanical tests at static loading because ...

Source: IOPscienceModeling the Static and Dynamic Behaviors of a Large Heavy-Duty ...

The static structural performance of a machine tool affects its load-carrying capacity and the geometric accuracy of the machined workpiece. The ...

Source: MDPIComparative study of the static and quasi-static compliance ...

Static load effects are caused by the limited static stiffness of the structural loop. These static and quasi-static loads are a consequent of workpiece weight, ...

Source: DiVA portalStiffness and Strength: Materials for Precision Machine Design

... load – static or dynamic, intended or unintended? How can we optimize the design – in terms of cost, weight, or some other performance ...

Source: Practical Precision

ALL

ALL Precision Machinery

Precision Machinery

Related Discussions