Summary

This article serves as an essential guide to linear bearings, exploring their significance in precision machinery and how advancements are shaping their future. Key Points:

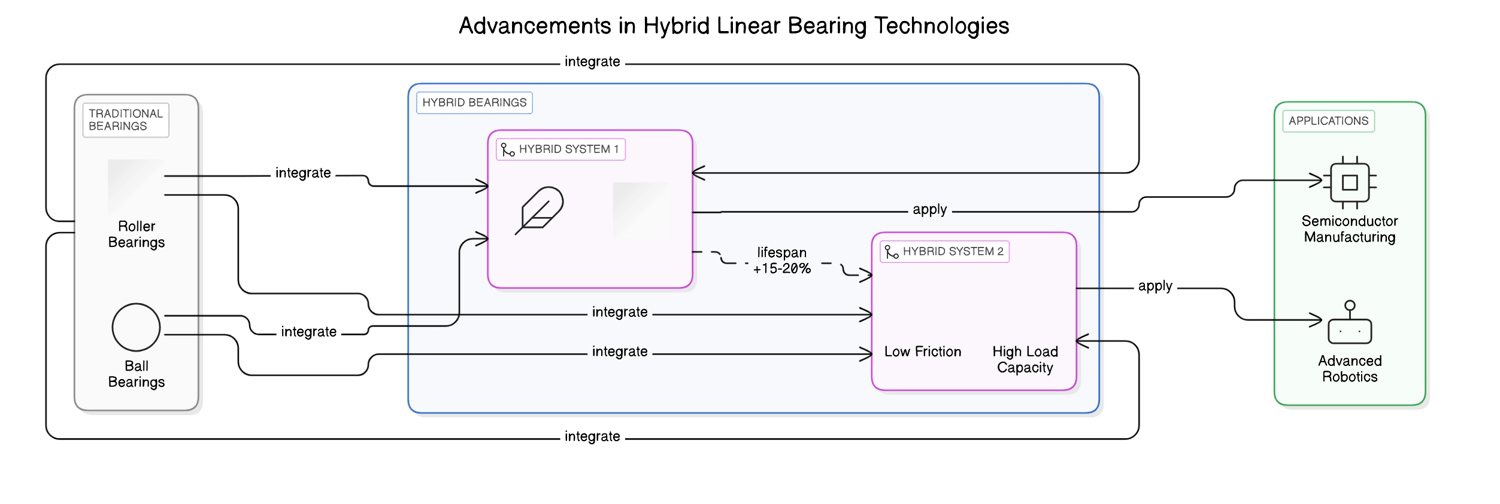

- Nanotechnology enhances the design of linear bearings with nano-coatings, achieving sub-micron accuracy and longer lifespan for demanding applications like semiconductor manufacturing.

- AI-driven predictive maintenance utilizes real-time data from sensors to foresee potential failures in linear bearings, minimizing downtime and cutting costs through optimized maintenance schedules.

- Sustainable materials development focuses on bio-based polymers that offer similar performance to traditional options while reducing environmental impact, paving the way for eco-friendly lubrication solutions.

What Makes Linear Bearings the Right Choice for Your Application?

A Manufacturer`s Linear Bearing Nightmare: From Initial Failure to Near Disaster

Mark shook his head in disbelief. “But we ran all the simulations! How did we miss that?”

It was Friday afternoon when disaster struck—the conveyor system jammed during testing. The grinding noise echoed through the workshop like a bad omen. “This can’t be happening,” Mark muttered as he stared at the screen filled with error codes.

“I thought we were ready,” Sarah said softly, her confidence shaken. “I honestly didn’t think it would be this hard.”

With potential delays looming and contracts slipping away like sand through their fingers, they realized how thin their margin for error had been—time was running out fast and nerves were fraying in ways they hadn’t anticipated.

| Key Insights | Implications | Recommendations | Tools/Technologies | Future Trends |

|---|---|---|---|---|

| Integration of sensor technology in linear bearings enhances predictive maintenance. | Reduces unplanned downtime by 30-40%. | Evaluate and implement smart linear bearings in high-performance applications. | Real-time monitoring systems, advanced sensors. | Increased adoption of integrated sensors for predictive maintenance. |

| Hybrid ceramic/steel linear bearings offer significant advantages over traditional options. | Reduce positional errors by up to 50% in precision applications. | Consider hybrid bearings for projects requiring high precision and load capacity. | Manufacturer data sheets detailing performance metrics. | Shift towards lighter, more efficient bearing designs with advanced materials. |

| Self-lubricating options can lead to a 50% reduction in maintenance interventions. | Lower long-term operational costs and increased uptime. | Explore self-lubricating bearings for challenging environments with limited access. | Advanced polymer composites, embedded PTFE materials. | Rising interest in automated lubrication systems. |

| Maglev technology presents both opportunities and challenges in the bearing market. | Potentially redefines motion control but may complicate simpler tasks. | Assess the suitability of Maglev technology on a case-by-case basis. | Cost-benefit analysis tools, expert consultations. | Ongoing debate between traditional vs. advanced bearing solutions. |

| Installation practices significantly impact bearing performance and lifespan. | Improper installation leads to failures and costly downtimes. | Follow best practices during installation; consider additional training if necessary. | Calibration tools, torque wrenches, checklists for organization. | Emergence of new training programs focused on modern bearing technologies. |

Turning the Tide: How a Simple Linear Bearing Adjustment Saved the Day

Mark could sense it too—the unease creeping in like a shadow. “We need clarity here,” he insisted, but some employees had already begun flipping through manuals and data sheets with furrowed brows, while others simply stared blankly at their screens as if hoping an answer would materialize.

“Maybe we should have double-checked those specs?” Jake chimed in hesitantly from the back. His voice trembled slightly; clearly, he was feeling the weight of responsibility.

“I mean… we all thought it was good enough, right?” Lisa added quietly before falling silent again. The tension thickened like smoke in the air; doubts swirled around them as they realized this situation wasn’t just affecting their project—it was beginning to fracture their morale too.

Then suddenly—a loud crash echoed from across the room as another machine stalled unexpectedly. Everyone jumped at the sound; it felt like a jolt of reality crashing down upon them all. No one spoke up after that—just uneasy glances exchanged amidst a growing sense of dread that hung heavy over their heads.

Our Approach: Identifying and Solving Linear Bearing Selection Challenges

However, results were underwhelming. “We tested a different alignment method, but it didn’t yield any improvements,” Mark admitted, frustration evident in his tone. Some team members nodded in agreement, while others frowned at the data displayed on their screens.

“I still believe this could work if we tweak our approach a bit more,” Jake interjected hopefully. Yet Lisa countered, shaking her head skeptically. “But what if we just end up wasting precious time?” The tension thickened again as they faced uncertainty; everyone felt the weight of potential failure hanging over them like dark clouds. No one knew if their efforts would pay off in time for the big reveal.

Free Images

Free ImagesFrequently Asked Questions: Addressing Common Linear Bearing Concerns

For instance, if you're working in high-precision fields like semiconductor manufacturing or advanced microscopy, you might want to consider hybrid ceramic/steel linear bearings. These innovative designs combine the low friction and wear resistance of ceramics with the robust load capacity of steel, resulting in precision levels that can reduce positional errors by up to 50% compared to traditional all-steel options.

I remember when I first encountered these hybrid bearings; I was amazed at how they could maintain accuracy even under high-speed conditions! 💡 A little tip here: always consider factors like surface roughness (aim for Ra values below 10nm) and thermal expansion coefficients when making your choice. These details can significantly impact your project’s success.

In summary, rather than worrying about potential failures, focus on understanding your project's requirements and choose accordingly. The right linear bearing can make all the difference!

Beyond the Basics: Exploring Specialized Linear Bearing Types and Applications?

The Great Linear Bearing Debate: Ball vs. Roller vs. Linear Guides – Which Reigns Supreme?

Hands-on Guide: Selecting and Installing Linear Bearings for Optimal Performance

When it comes to optimizing your machinery's performance, choosing the right linear bearings is crucial. Linear bearings can significantly influence not only the efficiency of your project but also its long-term maintenance costs. In my experience, many people overlook self-lubricating options, thinking they are just a premium choice. However, these bearings can reduce maintenance interventions by up to 50%, making them an incredibly wise investment.

**Step 1: Assess Your Application Needs**

Begin by evaluating the specific requirements of your application. Consider factors like load capacity, speed ratings, and environmental conditions. For instance, if you’re working in a harsh or inaccessible environment where regular maintenance is challenging, self-lubricating linear bearings made from advanced polymer composites may be the best fit.

**Step 2: Research Bearing Types**

Once you have a clear understanding of your needs, dive into researching different types of linear bearings available on the market. Self-lubricating options often utilize materials like embedded PTFE that provide excellent wear resistance while minimizing friction. Look for manufacturer data sheets that detail their performance under various loads and temperatures—this will guide you in selecting the right bearing type.

**Step 3: Gather Necessary Tools**

Before installation begins, ensure you have all necessary tools at hand:

- A clean workspace to avoid contamination

- Calibration tools for precise alignment

- Torque wrenches for proper fastening

- Lubricants (if applicable) based on bearing type

(As a personal tip: I always keep a checklist nearby! It helps me stay organized during installations.)

**Step 4: Installation Process**

Now it's time for the installation! Follow these steps:

1. **Clean Surfaces:** Ensure that both the mounting surfaces and bearings are free from debris.

2. **Align Bearings:** Position them according to specifications; proper alignment is key to optimal performance.

3. **Secure Mounting:** Use torque wrenches to fasten screws according to recommended torque settings—this step cannot be skipped!

4. **Test Movement:** Before finalizing everything, manually test the movement to check for any misalignments or binding.

**Advanced Tips & Reminders**

If you're looking to further enhance your system’s reliability and performance after installation, consider implementing monitoring systems that track bearing temperature and condition over time—you’ll catch potential issues before they escalate! Additionally, if you want even more control over lubrication schedules (for non-self-lubricating options), think about automated lubrication systems; they can save valuable time in high-demand environments.

By following these steps carefully and considering self-lubricating linear bearings as part of your solution set, you'll set yourself up for success in both current projects and future endeavors!

The Future of Linear Motion: What Innovations Lie Ahead for Linear Bearings?

Conclusion: Mastering Linear Bearings for Smooth, Reliable Motion – Your Next Steps

Now is the time to evaluate how these innovative strategies can be integrated into your own processes. Are you ready to harness the power of real-time data monitoring and predictive algorithms? By adopting this proactive maintenance approach, you can transform your operations from merely reactive to strategically optimized.

Remember, this trend won't slow down—it's evolving rapidly. How will you adapt to stay ahead? Explore these advancements today and take the next steps towards elevating the effectiveness of your equipment. Embrace the future of linear bearings and unlock new potential in your projects!

Reference Articles

Essential Guide to Linear Bearings: Choosing the Right Type ...

When selecting the right linear bearing for your needs, it's essential to take a holistic approach that goes beyond just specifications.

Source: kantti.netHow to Choose the Right Linear Guide System for Your Project ...

Consider the type of motion the system will have to accommodate, whether it's simple back and forth movement, complex multi-axis motion, or circular motion.

Source: smoothmotor.comUltimate Guide to Linear Bearings: Types, Construction ...

Factors to consider when choosing a mounting method include load capacity, accuracy requirements, environmental conditions, and accessibility ...

How Do You Choose a Linear Bearing?

The choice of bearing type depends on factors like load capacity, rigidity, and the environment in which it will operate. The chart below will ...

Source: motionplusmore.comLinear Guide Selection and Calculation

It is important when selecting a linear bearing to know the basic load rating, the dynamic load rating, and the maximum load a linear bearing ...

Source: motionplusmore.comHow To Choose The Best Linear Guide For Your Applications

Whether you are opting for profile, flat, round or square guides, choosing wisely ensures seamless and easy mechanical operation.

Source: SLS BearingsChoosing The Right Linear Guide For Your Project

In the industry, there is a convenient acronym, 'LOSTPED', which represents the factors that must be considered when choosing a linear guide: ...

Source: Accuride EuropeHow to Choose the Right THK Linear Bearings for Your Project ...

This article will guide you through the essential factors to consider when selecting THK linear bearings for your project. Understanding THK Linear Bearings.

Source: ws-thk.com

ALL

ALL Precision Machinery

Precision Machinery

Related Discussions