Summary

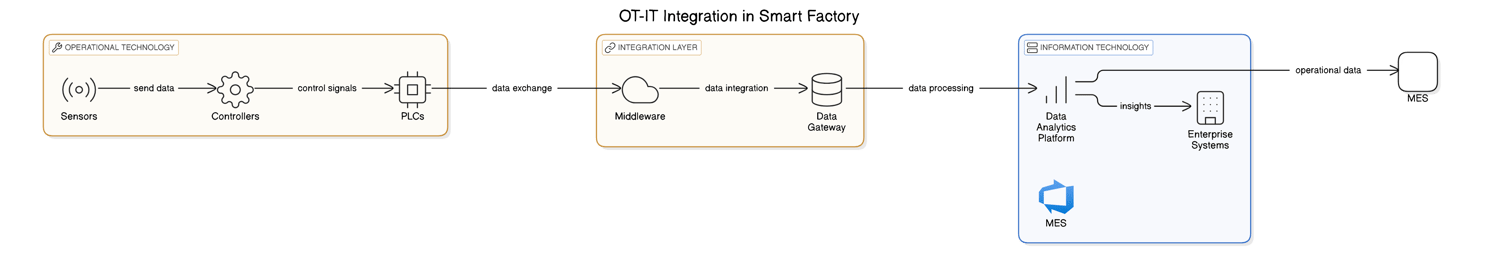

In today`s rapidly evolving industrial landscape, the convergence of Operational Technology (OT) and Information Technology (IT) is crucial for unlocking the full potential of smart factories. Understanding this integration helps businesses enhance security, efficiency, and reliability. Key Points:

- Implementing Zero Trust Architecture enhances security in OT-IT integration by utilizing micro-segmentation and continuous authentication to protect against cyber threats.

- AI-driven predictive maintenance allows for real-time failure predictions, optimizing equipment performance while detecting potential anomalies before they escalate.

- Digital twins facilitate operational efficiency through virtual simulations, enabling proactive risk assessment and streamlined training programs.

Understanding the Importance of OT-IT Integration

**Who Should Read This Blog?**

**Target Audience:**

1. **C-Level Executives (CEO, COO, CTO, CIO):**

**Why It Matters:** Discover how integrating operational technology (OT) with information technology (IT) can drive business growth, enhance operational efficiency, and provide a competitive edge.

2. **Operations and Plant Managers:**

**Why It Matters:** Learn about effective strategies to boost production efficiency and minimize downtime by leveraging real-time monitoring and predictive maintenance techniques.

3. **Quality Assurance Managers:**

**Why It Matters:** Explore how integrated quality management systems can significantly improve product quality while ensuring compliance with industry standards.

4. **Maintenance Managers:**

**Why It Matters:** Uncover methods to reduce unexpected downtime and streamline maintenance processes using predictive maintenance approaches.

5. **Supply Chain Managers:**

**Why It Matters:** Gain valuable insights into improving supply chain visibility and efficiency through cohesive data systems that promote better decision-making.

6. **IT Managers and Directors:**

**Why It Matters:** Understand how to manage and implement successful OT-IT integration projects, paying close attention to system interoperability, data security measures, and scalable solutions like cloud platforms for efficient data storage.

In this blog series, we will delve deeper into these aspects of OT-IT integration in industrial environments—highlighting key principles such as real-time data sharing between technologies and interoperability that is crucial for optimizing operations across various sectors. We will also discuss specific tools like edge computing devices that enable local processing for quicker insights while maintaining robust cybersecurity protocols to protect integrated systems against potential threats—ensuring both performance integrity and data security are upheld throughout the process.

Who Should Care About OT-IT Integration

**7. System Integrators and Solution Architects: Why It Matters:** These professionals gain valuable insights into designing and deploying integrated systems that link OT with IT by utilizing middleware solutions and edge computing.

**8. Data Scientists and Analysts: Why It Matters:** It's crucial for these experts to understand how to extract value from the data generated by integrated systems for advanced analytics and AI-driven insights.

**9. Cybersecurity Specialists: Why It Matters:** These specialists need to focus on securing integrated systems against cyber threats through implementing robust security measures.

**10. IoT Engineers: Why It Matters:** Discovering best practices for the implementation and management of IoT devices within integrated systems is essential for these engineers.

Understanding who stands to benefit from OT-IT integration is vital across various roles in industries today. Manufacturing executives should recognize that this integration can significantly enhance their data analytics capabilities, leading to better decision-making processes. IT professionals must appreciate how integrating OT can streamline workflows and minimize downtime, while supply chain managers should see that smooth data exchange between OT and IT allows them to optimize inventory management strategies and respond quickly to market fluctuations—ultimately boosting overall operational efficiency throughout production cycles.

| Target Audience | Key Insights | Importance of OT-IT Integration | Best Practices |

|---|---|---|---|

| C-Level Executives | Integrating OT and IT drives business growth and operational efficiency. | Provides a competitive edge in the market. | Establish a clear strategy. |

| Operations and Plant Managers | Real-time monitoring boosts production efficiency. | Minimizes downtime through predictive maintenance. | Utilize edge computing for real-time data processing. |

| Quality Assurance Managers | Integrated quality management enhances product quality. | Ensures compliance with industry standards. | Adopt a unified platform for seamless integration. |

| Maintenance Managers | Predictive maintenance reduces unexpected downtimes. | Optimizes maintenance processes based on actual usage patterns. | Prioritize security measures to protect sensitive data. |

| Supply Chain Managers | Improved visibility and efficiency through cohesive data systems. | Facilitates better decision-making within supply chains. | Emphasize scalability in integration architecture. |

What is Industry 4.0 and Its Implications

**Understanding OT and IT:** - **Operational Technology (OT):** This term encompasses the hardware and software systems utilized for monitoring and controlling physical processes within industrial settings. Examples include SCADA systems, Programmable Logic Controllers (PLCs), and Manufacturing Execution Systems (MES). - **Information Technology (IT):** In contrast, IT refers to the array of computer-based tools used for storing, retrieving, transmitting, and processing information. Typical IT systems consist of Enterprise Resource Planning (ERP) software, Customer Relationship Management (CRM) tools, and various data analytics platforms.

--- **The Significance of Integrating OT with IT in Today’s Manufacturing Landscape:** The integration of OT with IT is crucial as it connects the tangible operations occurring on the production floor with the broader digital processes across an organization. This convergence plays a vital role in establishing a cohesive manufacturing environment that enhances efficiency. By enabling smooth communication between these domains, companies can leverage advanced technologies such as cyber-physical systems, IoT connectivity, edge computing devices, and sophisticated sensors to drive innovation while ensuring predictive maintenance through AI-driven insights. Ultimately, this fusion leads to improved operational effectiveness in smart factories while fostering an agile response to market demands.

Defining Operational Technology and Information Technology

**2. Facilitating Predictive Maintenance:** Li Wei, the maintenance supervisor, previously relied on scheduled maintenance routines for the machinery. Despite his diligence, unexpected equipment failures were common, resulting in costly downtimes. Thanks to the integration of OT and IT systems now equipped with continuous health-monitoring sensors on each machine, he can proactively track performance indicators. This shift not only helps avoid unplanned breakdowns but also optimizes maintenance schedules based on actual usage patterns rather than just estimates.

Free Images

Free ImagesHow OT-IT Integration Enhances Manufacturing Efficiency

Meanwhile, Afzal, who operated the production line, used to face challenges with making manual adjustments whenever production requirements changed. However, after integrating smart manufacturing practices through OT-IT collaboration, these adjustments became automated. Now, the system can dynamically modify the production line based on real-time data, allowing Afzal to concentrate more on quality control. This newfound flexibility has enabled ABC Manufacturing to respond promptly to shifting market demands while optimizing production schedules and minimizing waste.

In another part of the operation, Michael, the operations director, often found himself needing to make decisions based on incomplete or outdated information.

Real-Life Benefits of Integrating OT and IT Systems

However, integrating OT within the context of Industrial IoT presents certain challenges. One significant hurdle is the existence of diverse and legacy systems. The integration process involves coordinating various old and new machinery that operate on different protocols, which can complicate efforts to streamline operations effectively.

Challenges Faced in Implementing OT for Industrial IoT

Another challenge lies in maintaining **data quality and consistency** across diverse platforms. With various systems in play, ensuring that data remains high-quality and reliable can be quite complex. Additionally, organizations often face **silos**, where OT and IT departments operate independently. Bridging this gap is essential for fostering collaboration and enhancing overall efficiency.

Moreover, as companies look to implement these solutions, they must consider **scalability**—the ability for an integration solution to expand seamlessly from a pilot phase to full-scale operation. Addressing these factors not only helps in overcoming obstacles but also paves the way for successful implementation of OT within industrial IoT environments.

Key Considerations When Integrating OT and IT Systems

Next, ensuring interoperability is key. Utilizing standardized protocols and middleware can facilitate seamless data exchange between various systems, making communication more efficient.

Security is another major concern that cannot be overlooked. It's essential to implement strong cybersecurity measures to safeguard against potential threats that could compromise system integrity or data confidentiality.

Lastly, managing data quality should be a priority. Establishing governance practices will help maintain consistent and high-quality data across integrated platforms. By focusing on these considerations, organizations can pave the way for successful OT-IT integration that supports their operational goals while addressing any challenges that may arise along the way.

Best Practices for Successful OT-IT Integration

Conclusion: Unlocking the Potential of Integrated Industrial Operations

---**Conclusion:** The integration of OT and IT is vital for harnessing the benefits of Industrial IoT, laying the groundwork for smarter and more efficient industrial processes. By recognizing the significance of this integration, paying attention to key considerations, and adhering to best practices, industries can fully leverage their data to achieve remarkable gains in performance, productivity, and innovation. As you embark on your journey toward OT-IT integration, keep in mind that having a clear strategy, implementing strong security measures, and fostering collaboration are essential components for success.

### The Challenges of Operating in Silos: Understanding the Necessity for OT-IT Integration in Industry**

Reference Articles

Maximizing Industrial IoT Potential with OT-IT Integration

Why It Matters: Learn how OT-IT integration drives business growth, operational efficiency, and competitive advantage.

Source: Medium · Prashanth Y PIT and OT convergence holds the key to unlocking ...

Integration opens the door for predictive, preventive, and ultimately prescriptive maintenance. But it also clears the way for digital twin ...

Source: CognizantMaximizing Industrial IoT Potential with OT-IT Integration

Explanation: As OT-IT integration expands, cybersecurity becomes increasingly critical. Protecting integrated systems from cyber threats is ...

Source: Medium · Prashanth Y PIT/OT Convergence in Manufacturing: Steps to Achieve a ...

By integrating IT and OT, manufacturers can leverage real-time data, enhance decision-making, and optimize operations across the board. IT/OT ...

Source: MatellioHow IT/OT convergence enables smart manufacturing

IT/OT convergence is enabling smart manufacturing through data-driven decisions that can improve efficiency, productivity and ...

Source: SiemensWhat are the benefits of OT and IT integration?

The OT can benefit from this integration with a more efficient, scalable, managed and secured infrastructure onto which numerous applications are layered.

Source: Eurotech

ALL

ALL Precision Machinery

Precision Machinery

Related Discussions